|

WORKSHOP CRIMPERS

S10

LxWxH: 690x600x1400 mm

| | S10 |

|---|

| Crimp Force (kN / Ton) |

2800 / 280 |

| No Grease: 20 % less friction |

|

| Control |

Control A |

| SAE R 15 / 4SH* - 1 piece |

2“ |

| 4SH* - 2 piece |

2“ |

| SAE R 15* - 2 piece |

2“ |

| Industrial |

4“ |

| 90° Elbows |

2“ |

| Crimp range |

139 mm |

| Opening |

+45 mm |

| Opening without dies |

190 mm |

| Type of dies |

239 L / 237 L** |

| Speed |

Close: 6,1 mm/sec.

Crimp: 1,7 mm/sec.

Open: 10,3 mm/sec. |

| Noise level |

69 dBA |

| Drive |

5,5 kW |

| Oil |

55 l |

| Weight |

390 kg |

|

| Type of dies | 239 L | 237 L ** |

|---|

| Ø mm |

mm |

mm |

| 6,8 |

40 |

|

| 9 |

70 |

|

| 12 |

70 |

|

| 14 |

70 |

|

| 16 |

70 |

|

| 17 |

70 |

|

| 19 |

70 |

|

| 20 |

70 |

|

| 22 |

70 |

|

| 24 |

70 |

|

| 26 |

70 |

|

| 28 |

85 |

|

| 32 |

85 |

|

| 36 |

85 |

|

| 40 |

85 |

|

| 44 |

85 |

|

| 47 |

110 |

|

| 50 |

110 |

|

| 54 |

110 |

118 |

| 57 |

110 |

118 |

| 62 |

110 |

118 |

| 67 |

|

118 |

| 71 |

|

118 |

| 74 |

|

118 |

| 78 |

|

118 |

| 84 |

|

118 |

| 86 |

|

118 |

| 90 |

|

118 |

| 96 |

|

118 |

| 103 |

|

118 |

| 106 |

|

126 |

| 111 |

|

126 |

| 116 |

|

126 |

| 121 |

|

126 |

| 126 |

|

126 |

| 131 |

|

126 |

|

S10 Package = Machine + PB Ø 17, 20, 24, 28, 32, 40, 44, 50, 57, 71 + 237.239.2L2

* According to the fitting.

** Intermediate dies not required.

*** Only with Control B+ Touch.

# Option available only on purchasing

INCLUDED

QDS 239 B

QDC 239.5

OPTIONS

CONTROL B+Touch#

UTS*** #

UTS enables a comfortable article entry via the PC. The data can be entered in a set MS Excel-sheet and be transferred with UTS to the UNIMATIControl-B + TOUCH. Therefore it is possible to compare the data from a number of machines, provide documentation (date + time), back-tracking and backup in one go. All crimpings can be documented with UTS, especially with the PFM option, which saves the pressure value as additional parameter.

OIL COOLER

Prevent the heating of hydraulic oil.

A constant oil temperature leads to reproducable crimp results.

PS*** #

To close the crimper.

TA (depht stop)

To position the fittings inside the head and/or to complete the crimp cycle automatically.

QDS 239 C

Mobile die storage

239 / 239 L (12 or 24 set)

and 232 L (2 or 4 Set).

* C is with only one shelf.

** T is with 2 shelf.

PTS system

Marking and crimping in one step according to

DIN 20066 and EN 853, EN 854, EN 856, EN 857.

PTS 52

Character 4 x 2,0 mm / marking depth ca. 0,3 - 0,5 mm

PTS 32

Character 3 x 1,5 mm / marking depth ca. 0,3 mm

QDS 239 S

To store dies directly at the machine, to bolt on the wall (for 239 / 239 L and 232L) or on the table.

SHS

Allows the operator to watch the correct position of the part to be crimped behind the machine.

LUS / LUF

Light for the rear site of the machine.

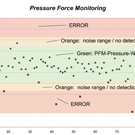

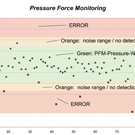

PFM

PFM (Pressure Force Monitoring) gives you the option to achieve a substantial quality improvement for a comparatively small investment of time and money. And here is how it works...

After each crimp process with the PFM-Option the reached crimp value is shown. Out of these measures the start values for the upper- or lower pressure limit can be determined. During each crimp process the permanently measured crimp value is compared to the entered limits. If this exceeds the set limits, an error message is shown. In the end of the crimp process it is tested once more if the minimal pressure has been reached. In the case of an error the operator has the option to check the work piece thoroughly and to correct any sources of the error.

During a detailed examination with the PFM-option the quality of a production process was increased from 97,8% to 99,7%. 2% of all produced parts had defects and with the UNIFLEX PFM option it was prevented that these defective parts were delivered to customers.

|

Folletos digitales

Descarga gratuita de la última versión de Adobe Acrobat Reader.

MANGUERAS HM_2021-03(x).pdf

English, Italiano, Français, Deutsch, Español, Português

ACOPLAMIENTOSCM_2015-11d(x).pdf English, Italiano, Français, Deutsch, Español, Português. MÁQUINAS Y EQUIPOS DE HERRAMIENTASME_2014-10Mb(x).pdf English

|