|

Series 3 - Interlock

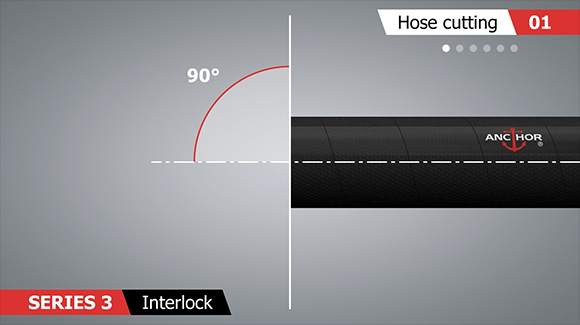

01 Hose cutting

| The hose end has to be cut squarely, check that the hose wire does not show any deformation and interference with the liner and hose cover. To avoid wire deformation the blade has to be periodically sharpened. |

|

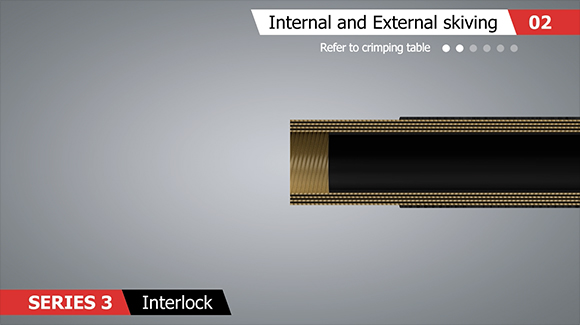

02 Internal and external skiving

Remove the cover until reaching the wire as indicated in the crimping data table and check the conformity.

Remove the inner tube until reaching the wire as indicated in the crimping data table and check the conformity. |

|

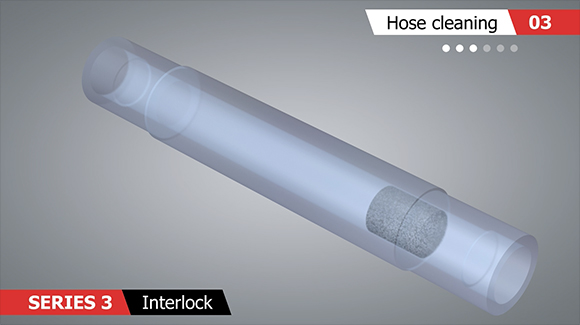

03 Hose cleaning

| To remove internal impurities clean the entire hose length before inserting the couplings. The level of internal assembly cleanliness must be prior defined between seller and customer. The videoclip shows a foam projectile being pushed through a hose in order to remove contaminants that can damage hydraulic system components. |

|

Coupling identification and check

Be sure that the coupling to be used for the assembly corresponds to CFS’s indications.

Note of the traceability code marked on ferrule under the part number code. In case of a claim it will be requested by CFS Customer Service.

|

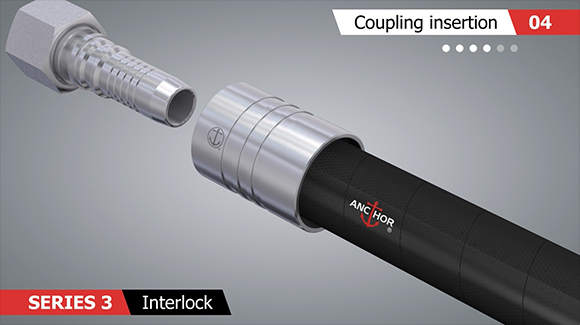

04 Coupling insertion

| For easier insertion it is possible to apply W10 hydraulic oil to the stem. |

|

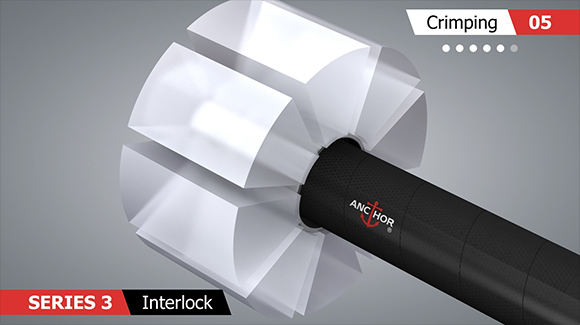

05 Crimping

| Place the coupling / ferrule between the dies and complete the crimping phase. For all spiral hose the crimping style is full ferrule length: “FLAT”. |

|

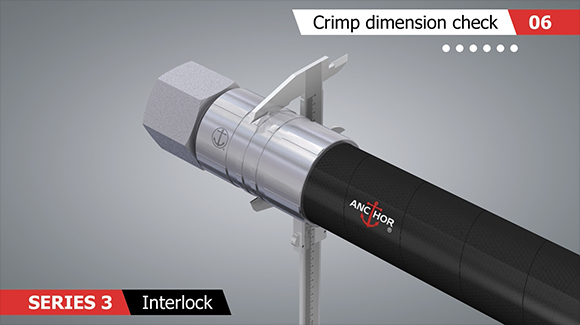

06 Crimp dimension check

| Check the crimp diameter. |

|

|

Digital Brochures

Free download of the latest version of Adobe Acrobat Reader.

HOSES HM_2021-03(x).pdf

English, Italiano, Français, Deutsch, Español, Português

COUPLINGSCM_2015-11d(x).pdf English, Italiano, Français, Deutsch, Español, Português. MACHINES AND TOOLING EQUIPMENTME_2014-10Mb(x).pdf English

|